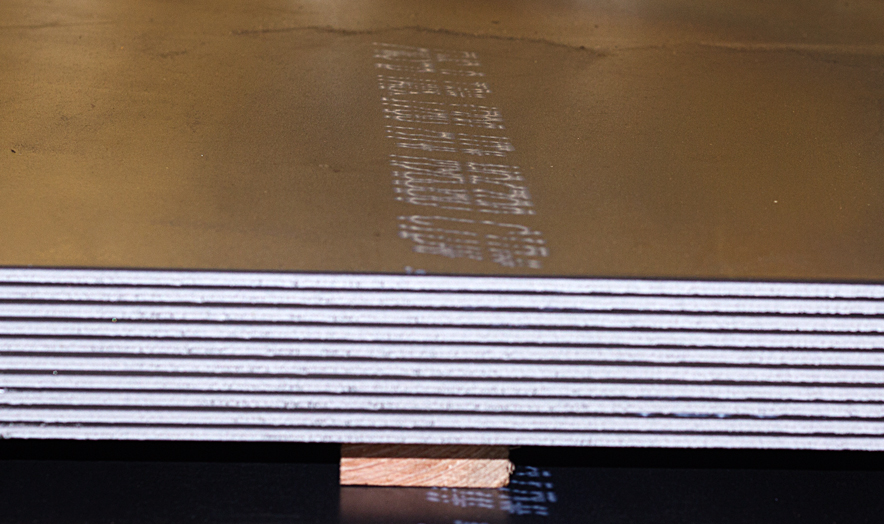

Heat Treat & Abrasion Resistant Plate

Farwest invests in an extensive abrasion resistant steel plate inventory.

Heat Treat & Abrasion Resistant Steel

Heat treat & abrasion resistant steel are vital materials for industries that require exceptional durability and performance. This type of steel undergoes specific heat treatment processes to enhance its mechanical properties, making it perfect for applications that demand high resistance to wear. Understanding the intricacies of heat treating and the attributes of abrasion resistant steel can help you make informed decisions for your projects. At Farwest Steel, we provide a variety of products crafted to meet the stringent needs of your industry, ensuring you have the right material for every application, including AR steel plate and wear resistant plate options.

Understanding Heat Treating

Heat treating is a critical process in steel production, involving the controlled heating and cooling of steel to modify its physical and sometimes chemical properties. The main goal of heat treating is to improve the steel’s performance characteristics, such as hardness, ductility, and strength, making it suitable for various demanding applications.

Common heat treatment processes include quenching, which rapidly cools the steel in water or oil to harden it. This is often followed by tempering, where the steel is reheated to a specific temperature and then cooled again to decrease brittleness while maintaining hardness.

The benefits of heat treating are significant, particularly in enhancing the mechanical properties of steel. This makes heat treated steels ideal for applications needing durability and resilience, such as construction equipment, machinery, and various industrial tools. At Farwest Steel, we understand the importance of these processes in producing high-quality heat treat & abrasion resistant steel, including options like A514, 400F, and 500F, that meet the demands of our customers.

What is Abrasion Resistant Steel?

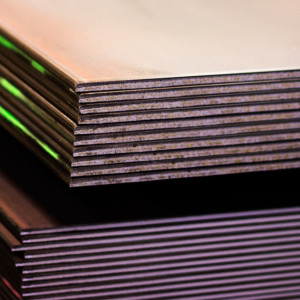

Abrasion resistant steel (AR steel) is engineered to endure wear and tear in challenging environments. The typical hardness levels of abrasion resistant steel range from 450 to 600 BHN (Brinell Hardness Number), ensuring durability and an extended service life.

Various industries benefit from abrasion resistant steel, including construction, agriculture, and material handling. In construction, AR steel plates are commonly used in dump truck beds, excavator buckets, and other heavy machinery components subjected to harsh conditions.

Abrasion resistant steel is available in several grades, each tailored for specific applications. The choice of grades depends on the specific demands of the application; for instance, AR400 offers good flexibility while maintaining wear resistance, making it suitable for moderate to heavy-duty applications, whereas AR500 is ideal for the most demanding environments where maximum abrasion resistance is necessary.